37 make a copy of the isothermal transformation diagram for an iron-carbon alloy

Fig.4: Time temperature transformation (schematic) diagram for plain carbon eutectoid steel t 1 t 2 t 3 t 4 t 5 M F, Martensite finish temperature M 50, 50% Martensite M S, Martensite start temperature Metastable austenite +martensite Martensite e 0 100 e Log time Hardness A e1 T 2 T 1 50% T T 2 1 Pearlite Fine pearlite Upper bainite Lower bainite (a) How long will it take for the austenite-to-pearlite reaction to go to 50% ... the isothermal transformation of an iron-carbon alloy of eutectoid.

Below is shown the isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy. List the microconstituent(s) present for the heat treatment labeled (a) on this diagram. It is not necessary to state the proportion(s) of the microconstituents.

Make a copy of the isothermal transformation diagram for an iron-carbon alloy

10.19 Make a copy of the isothermal transformation diagram for an iron–carbon alloy of eutectoid composition (Figure 10.22) and then sketch and label ... Make a copy of this figure 10.21 For parts (a), (c), (d), (f), and (h) of Problem 10.20, determine the approximate percentages of the microconstituents that form. 10.22 Make a copy of the isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy (Figure 10.39), and then sketch and label on this diagram the time-temperature paths to ... Isothermal transformation diagrams university of portland isothermal transformation diagrams 10 18 using the isothermal transformation diagram for an ironcarbon alloy of eutectoid position download free and get a copy in your email. 1019 using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in ...

Make a copy of the isothermal transformation diagram for an iron-carbon alloy. 10.19 Make a copy of the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22) and then sketch and label time-temperature paths on this diagram to produce the following microstructures: (a) 100% fine pearlite (b) 100% tempered martensite Make a copy of the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22) and then sketch and label on this diagram a time-temperature path that will produce 100% fine pearlite. Rank the following iron-carbon alloys and associated microstructures from Transcribed image text: 10.20 Make a copy of the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.23) and then sketch and label time-temperature paths on this diagram to produce the following microstructures: (a) 100% fine pearlite (b) 100% tempered martensite (c) 25% coarse pearlite, 50% bainite, and 25% martensite 800 A Eutectold temperature 700 ... Using the isothermal Transformation Diagram for An Iron-carbon Alloy Of Eutectoid Composition. solved 10 19 using the isothermal transformation diagram 10 19 using the isothermal transformation diagram for an iron carbon alloy of eutectoid position figure 10 22 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small ...

Make a copy of the isothermal transformation. diagram for an iron-carbon alloy of eutectoid. composition (Figure 10.22) and then sketch and. label time-temperature paths on this diagram to. produce the following microstructures: (a) 100% coarse pearlite. (b) 50% martensite and 50% austenite. (c) 50% coarse pearlite, 25% bainite, and 25%. Make a copy of the isothermal transformation diagram for a 1.13 wt% C iron-carbon alloy (Figure 10.39), and then on this diagram sketch and label time-temperature paths to produce the following microstructures: (a)6.2% proeutectoid cementite and 93.8% coarse pearlite (b)50% fine pearlite and 50% bainite (c) 100% martensite (d)100% tempered ... FREE Answer to Make a copy of the isothermal transformation diagram for an iron–carbon alloy of eutectoid composition provided... 10.18 Below is shown an isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy, with time-temperature paths that will produce (a) 42% proeutectoid ferrite and 58% coarse pearlite; (b) 50% fine pearlite and 50% bainite; (c) 100% martensite; and (d) 50% martensite and 50% austenite.

Problem 3 Make a copy of the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22) and then sketch and label time-temperature paths on this diagram to produce the following. microstructures: (a) 100% fine pearlite (b) 50% coarse pearlite, 25% bainite, and 25% martensite a) 8. b) 760 580 500 9. Make a copy of the isothermal transformation diagram for an iron carbon alloy of eutectoid composition (Below) and then sketch and label time-temperature paths on this diagram to produce the following microstructures: (a) 100% coarse pearlite (b) 50% martensite and 50% austenite (c) 50% coarse pearlite, 25% bainite, and 25% martensite o 800 A ... Question. Make a copy of the isothermal transformation diagram for a 1.13 wt% C iron-carbon alloy, and then on this diagram sketch and label time-temperature paths to produce the following microstructures: (a) 6.2% proeutectoid cementite and 93.8% coarse pearlite. (b) 50% fine pearlite and 50% bainite. Using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition fi. 1018 using the isothermal transformation diagram for an ironcarbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in terms of microconstituents present and approximate percentages of each of a small ...

(a) How long will it take for the austenite-to-pearlite reaction to go to ... 10.18 Using the isothermal transformation diagram for an iron–carbon alloy of ...

Using the continuous-cooling transformation diagram for an iron-carbon alloy of eutectoid composition, Figure 10.28, name the microstructural products of specimens having this eutectoid compositions that are first completely transformed to austenite, then cooled to room temperature at the following rates: 175°C/s: 90°C/s: 15°C/s: 2 ...

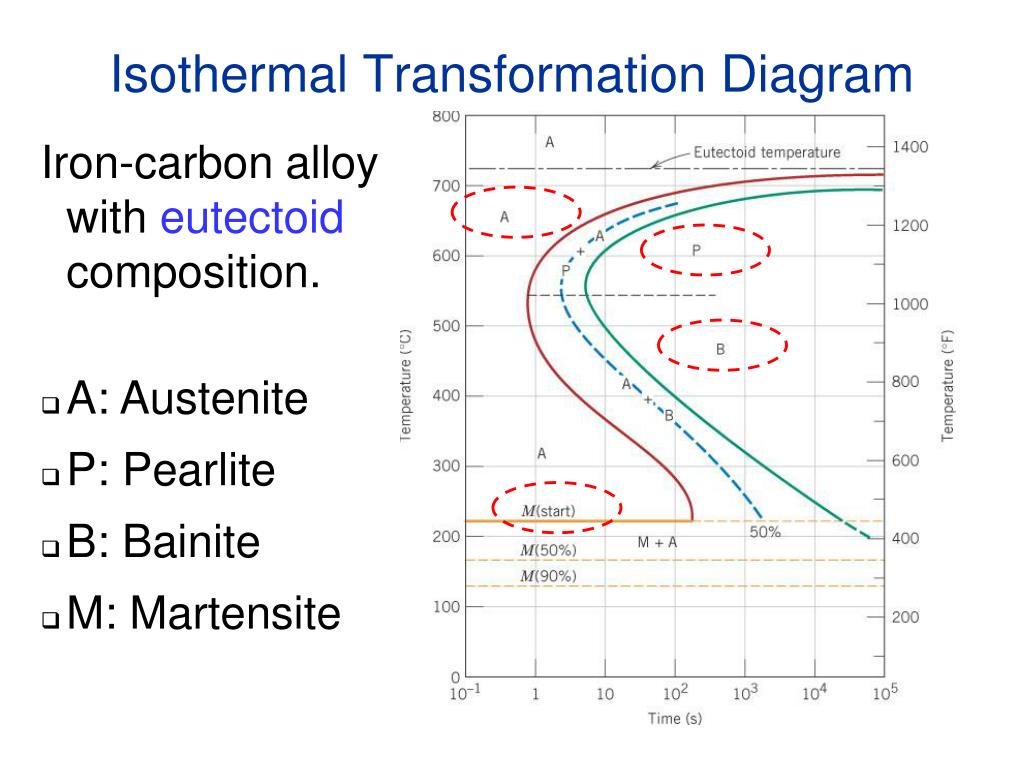

The complete isothermal transformation diagram for an iron-carbon alloy of eutectoid composition: A, austenite; B, bainite; M, martensite; P, pearlite. Martensite can only be formed with very rapid cooling rates Fig. 10.22 from Callister& Rethwisch, Materials Science & Engineering, An Introduction, 8 th ed., J. Wiley & Sons, 2010 7

Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain's curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

ENGR45: Introduction to Materials Fall 2016 Homework Set 8 - Solutions 8.1. (a) On the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition, sketch and label time-temperature paths that would produce the following microstructures: (i) 100% coarse pearlite (ii) 100% spheroidite (iii) 50% martensite and 50% austenite (iv) 50% coarse pearlite, 25% bainite and 25% ...

Hence, the final microstructure is 100% tempered martensite. 22 Make a copy of the isothermal transformation diagram for a 0. 45 wt% C iron-carbon alloy (Figure 10. 39), and then sketch and label on this diagram the time-temperature paths to produce the following microstructures:(a) 42% proeutectoid ferrite and 58% coarse pearlite(b) 50% fine ...

Using the continuous-cooling transformation diagram for an iron-carbon alloy of eutectoid composition, Figure 10.28, name the microstructural products of specimens having this eutectoid compositions that are first completely transformed to austenite, then cooled to room temperature at the following rates: 175°C/s: 90°C/s: 15°C/s:

10.21 For parts (a), (c), (d), (f), and (h) of Problem 10.20, determine the approximate percentages of the microconstituents that form. 10.22 Make a copy of the isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy (Figure 10.39), and then sketch and label on this diagram the time-temperature paths to produce the following microstructures: (a) 42% proeutectoid ferrite and 58% ...

the iron-carbon alloy system. A sample of the eutectoid composition is cooled from a single-phase region (γ) to a temperature (T) below the eutectoid temperature (T E). The following diagram shows a part of the iron-carbon phase diagram. Concentrations C 1, C 2, C 3, C 4 are various equilibrium ( stable as well as metastable ) concentrations ...

1 Answer to Make a copy of the isothermal transformation diagram for an iron–carbon alloy of eutectoid composition (Figure) and then sketch ...

65Dynamic Phase Transformations On the isothermal transformation diagram for 0.45 wt% C Fe-C alloy, sketch and label the time-temperature paths to produce the following microstructures: a) 42% proeutectoid ferrite and 58% coarse pearlite b) 50% fine pearlite and 50% bainite c) 100% martensite d) 50% martensite and 50% austenite.

1019 using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition. The thickness of the ferrite and cementite layers in pearlite is 81. Figure 1022 specify the nature of the final microstructure in terms of microconstituents present and. 6 Make A Copy Of The Isothermal Transformation Diagram For An Iron

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition. The nature of the final microstructure of the specimen which is subjected to various heat treatment processes can be found out by use of figure 1022 complete isothermal transformation diagram for an iron carbon alloy of eutectoid composition.

9.9 Is it possible to have a copper–nickel alloy that, at equilibrium, ... Make a copy of the isothermal transformation diagram for an iron–carbon alloy of ...

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure), specify the nature of the final microstructure (in terms of micro constituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

Make a copy of the isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy (Figure 10.39), and then sketch and label on this diagram the time-temperature paths to produce the following microstructures: (a) 42% proeutectoid ferrite and 58% coarse pearlite (b) 50% fine pearlite and 50% bainite (c) 100% martensite (d) 50% ...

10.19 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

Make a copy of the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22 ) and then sketch and label ...

Isothermal transformation diagrams university of portland isothermal transformation diagrams 10 18 using the isothermal transformation diagram for an ironcarbon alloy of eutectoid position download free and get a copy in your email. 1019 using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition figure 1022 specify the nature of the final microstructure in ...

Make a copy of this figure 10.21 For parts (a), (c), (d), (f), and (h) of Problem 10.20, determine the approximate percentages of the microconstituents that form. 10.22 Make a copy of the isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy (Figure 10.39), and then sketch and label on this diagram the time-temperature paths to ...

10.19 Make a copy of the isothermal transformation diagram for an iron–carbon alloy of eutectoid composition (Figure 10.22) and then sketch and label ...

0 Response to "37 make a copy of the isothermal transformation diagram for an iron-carbon alloy"

Post a Comment