39 pressure balancing loop diagram

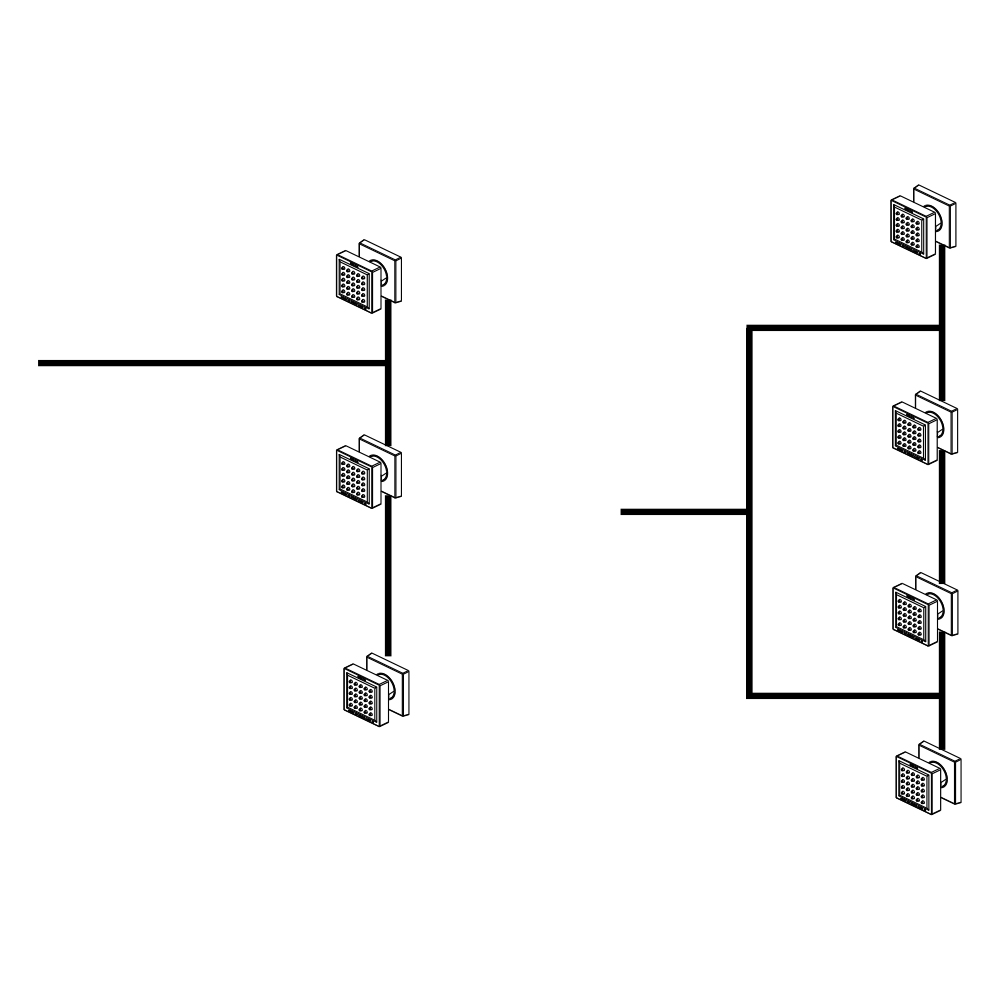

The piping common to both the secondary and primary loops are the two tees and the common piping shown above. Rule "1" tells us to keep that common pressure drop very low. The reason being if there is nothing to stop it, the pressure drop in that pipe will cause a flow in the secondary circuit, even if the secondary pump is off.

STUFF Variable Speed Pumping in Constant Volume or Pressure applications Use of VSP as throttling valve or control valve Pressure is maintained by impeller speed, so if pressure at pump needs to stay constant regardless of flow, may not be much advantage to VSP. Steep vs flat curves Domestic Water Booster If dominated by friction rather than lift, VFD is appropriate.

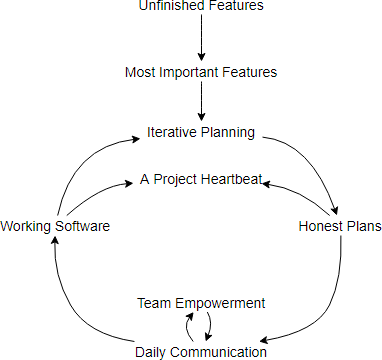

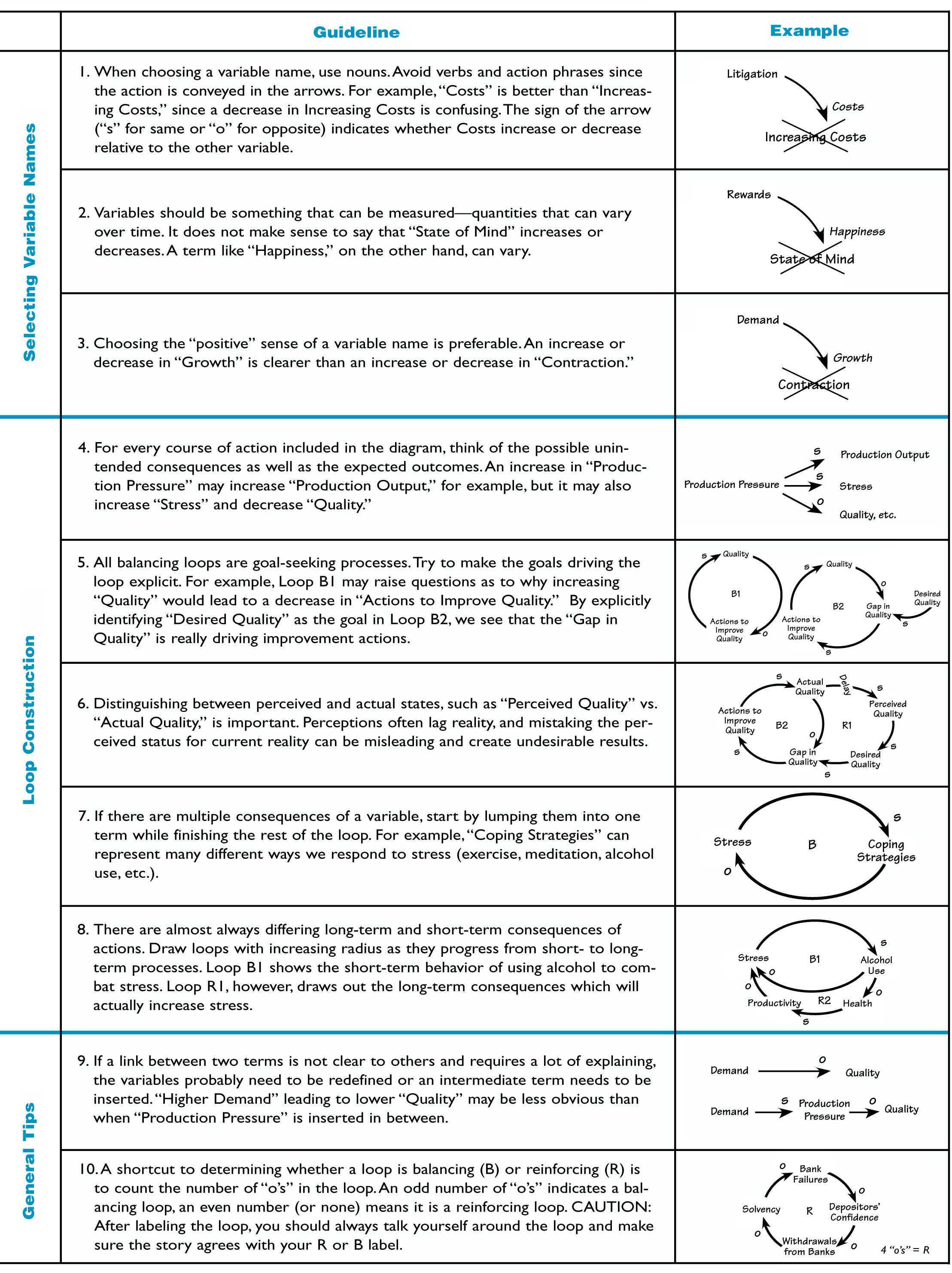

Diagrams Can Have Multiple Loops Learning by doing Loop The more the NGO achieved results in its work, the better its reputation. People Loop The better its reputation, the higher quality people it was able to hire, boosting its capacity. Money Loop Also, the better its reputation, the more funds were available, boosting capacity.

Pressure balancing loop diagram

60 - Voltage or Current Balance Relay 62 - Time-Delay Stopping or Opening Relay 63 - Pressure Switch 64 - Ground Detector Relay 65 - Governor 66 - Notching or jogging device 67 - AC Directional Overcurrent Relay 68 - Blocking or "out of step" Relay 69 - Permissive Control Device 71 - Level Switch 72 - DC Circuit Breaker 74 - Alarm Relay

opened If the pressure at the filter gauge drops substantially, or a flow meter on the main filtration line indicates that the pump is being short-circuited by excessive flow through the collector loop, one of the valves can be closed slightly to force more water through the filtration system

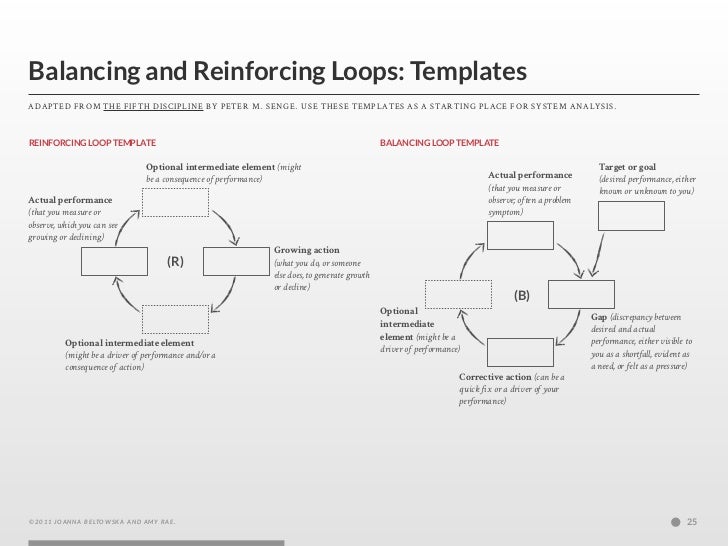

Causal loop diagrams map the causal relationships between pairs of elements within a system and identify feedback loops. These loops can either be reinforcing (vicious cycle) or balancing (goal-seeking) and complex interactions between loops can lead to unintended consequences. The arrows in the diagram describe the directions of effect.

Pressure balancing loop diagram.

Reinforcing Loop Balancing Loop Dynamic Behavior: Word of Mouth Sales Customers + + + Potential-Customers +-Graph for Customer 100,000 75,000 50,000 25,000 0 0102030405060708090100 Time (Month) Customer : Current

In causal loop diagrams, balancing loops are noted by a "B," a "—," or a scale icon in the center of a loop. The Structure of Balancing Loops. There is always an inherent goal in a balancing process, whether it is visible or not. The basic structure of a balancing loop involves a gap between the goal (or desired level) and the actual ...

http://www.tilemasterga.com In this video I am showing setup and installation of CUSTOM KOHLER SHOWER SYSTEM using Thermostatic and Volume control valves. P...

diagram, the standard control valves and balancing valves have been replaced with PICVs. Everything else stays the same. The loops are now balancing dynamically, meaning each loop is able to automatically and dynamically adjust for changes in the other loops since the PICV immediately responds to those differential pressure changes.

Loop Diagrams BAE 815 (Fall 2017) Dr. Zifei Liu ... Balancing loops can be automatic, or intentional policy. 14 Combination loops Births Dynamic behavior Deer population + R + Available food + B - ... Pressure for long-term fix-+ R Time Efforts quick fix Problem symptom Capacity of system

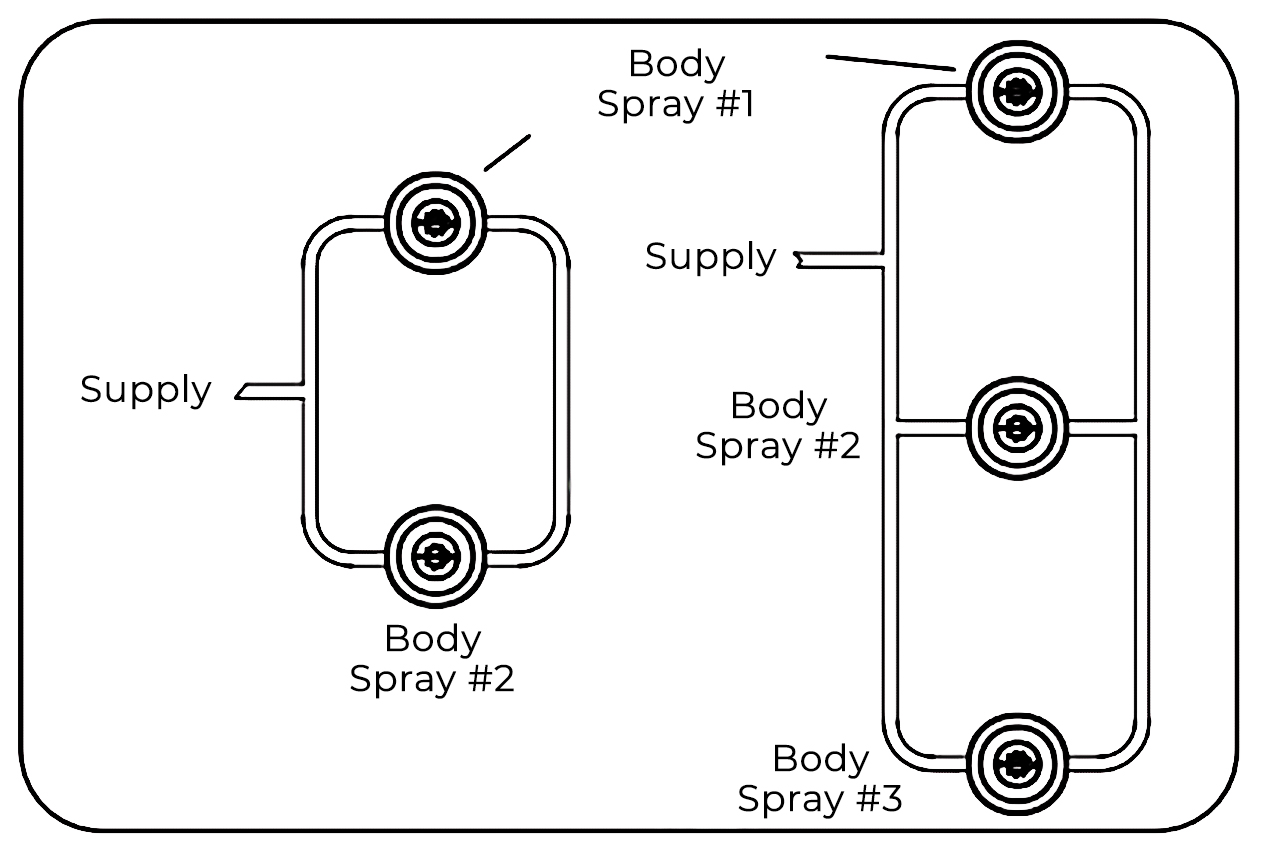

The key is the continuous loop for equal volume output. Depending on the GPM output and how many sprayers I will increase the loop size to 3/4" copper instead of the minimum size of 1/2" to help with the balancing. We use PEX and copper around here but I always use copper for my showers- after the valve. I will also make sure a 3/4" valve is ...

course of action included in the diagram. For example, an increase in "Production Pressure" may increase "Production Output," but it may also increase "Stress" and decrease "Quality" 5. All balancing loops are goal-seeking processes. Try to make explicit the goals driving the loop.

Compressed Air Basics - Piping. February 23, 2018. Your air compressor is the heart of your air system. Most customers focus on the compressor and consider the piping as a secondary concern. However, just like a heart can fail because of clogged arteries, a compressor can fail because of improper piping. You have many different options on the ...

A causal loop diagram (CLD) explains the behavior of a system by showing a collection of connected nodes and the feedback loops created by the connections. One or more of the nodes represent the symptoms of the problem. The rest of the nodes are the causal chains causing the problem.. The simplest possible CLD contains two nodes. Below is an example from video 3 in The Dueling Loops Video Series.

6. Name the loop: Give your loop a name! 7. Test and share your loops: Read the diagram as if you were telling a story. "As average com-muting times goes up, pressure to widen roads or add lanes goes up. As this pressure increas-es, the amount of new highway construction goes up. With more roads/lanes added, average commute time goes down.

8 NEW "SMART" PUMPS Speed varies without sensors High Efficiency ECM zElectronically Commutated Motor zA.k.a. DC Brushless Motor Integral VFD Sophisticated Electronics Residential to Light Commercial TYPE GPM HD (FT.) HP RPM HORIZ. IN-LINE 20 - 375 10 - 75 ¼ - 3 1760, 3500 END SUCTION 40 - 4,000 10 - 400 ⅓- 200 1160, 1760, 3500 VERTICAL IN-LINE 40 - 12,000 10 - 400 ¼ - 600 1160 ...

Edit this Diagram. Cause Loop Diagram Example - Growth and Investment. A Growth and Underinvestment structure is simply an elaborated Limits to Growth structure where the growth inhibitor is part of another Balancing Loop with an external standard and some delay.

B4, B5, B6 show the loops influencing political pressure. As balancing loops keep the system stable, these loops tend to absorb policy efforts and could hinder a wider change.

vidual thermostatic, pressure-balancing and combination pressure balancing and thermostatic control valves for in-dividual fixture fittings." ASSE Standard 1017 is the standard for compliance when selecting a three-way mixing valve for a central distribution system. Be sure to evaluate the accuracy, minimum and maximum flow rates,

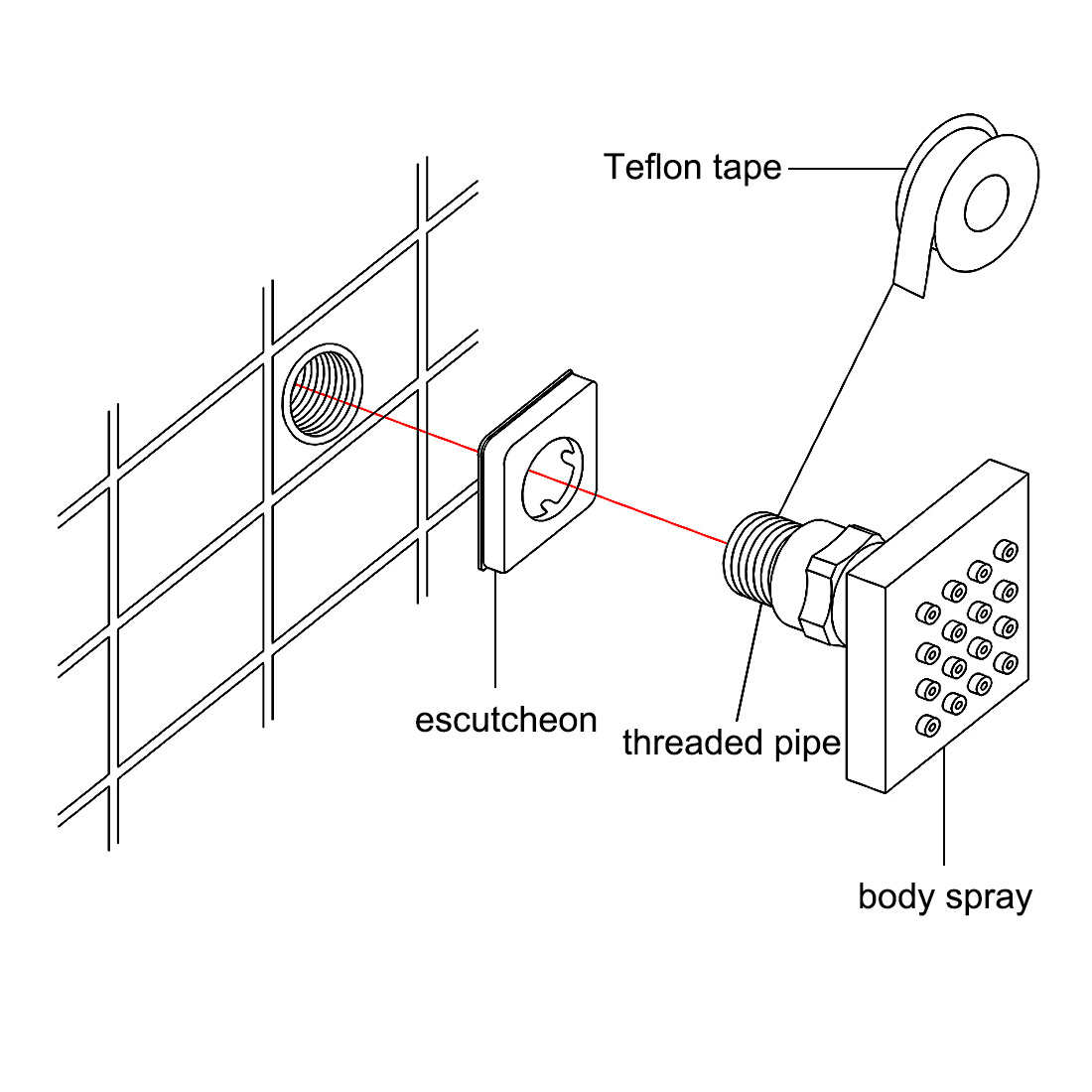

A pressure-balancing loop must always be used with body sprays to allow for equal supply of water to each spray. Maximum of 3 on 1 outlet. 2 body sprays may be operated as one function. Shower can be operated and personalized remotely with the U by Moen app, which is available for Android and iOS. Showerhead, Arm and Flange Handshower, Drop Ell ...

We differentiate between two kinds of feedback loops: balancing (or negative) feedback loops and reinforcing (or positive) feedback loops. The diagram above shows that if schedule pressure is high, then productivity is increased, which also increases the completion rate. This reduces the number of open tasks, which reduces the schedule pressure

I see how that would work but I've plumbed in a loop without the H configuration and I'm curious if I have to redo it. I would order the diagram you posted but these sprays are the R50200 I've mounted sideways. With the threaded conections I HAVE to loop it around to a tee then to the diverter. If the pressure is good I'm thinking I should be okay.

Figure 1: Typical block diagram for closed-loop control. Here, P denotes the plant, the system to be controlled, and C denotes the controller, which we design. Sensors and actuators are denoted y and f, respectively, and d denotes external disturbances. The − sign in front of f is conventional, for negative feedback. Reduce sensitivity.

A term to express pressure drop in a closed loop system • What produces head loss? Friction of the water rubbing against the pipe as it flows through the system. • 1 PSI of pressure drop = 2.31 feet of head • Does height of the building influence head loss? No • Why?It's a circulator, not a pump. It's a closed loop system and the ...

Caleffi North America, Inc. 9850 South 54th Street Franklin, WI 53132 T: 414.421.1000 F: 414.421.2878 Dear Hydronic Professional, Welcome to the 2nd edition of idronics - Caleffi's semi-annual design journal for hydronic professionals.

(3) Expansion loop: Thermal expansion loops are normally set for lengthy and high-temperature service lines such as an HP steam line and flare line. Since expansion loops increase equivalent length considerably, confirm Piping Section for the expected numbers if pressure balance is tight under selected pipe size.

"Production Pressure"is inserted in between them. 10.A shortcut to determining whethera loop is balancing or reinforcing is to count the number of "o's" in the loop. An odd numberof "o's" indicates a balancing loop (i.e., an odd numberof U-turns keeps you headed in the opposite direction); an even num-

0 Response to "39 pressure balancing loop diagram"

Post a Comment